1

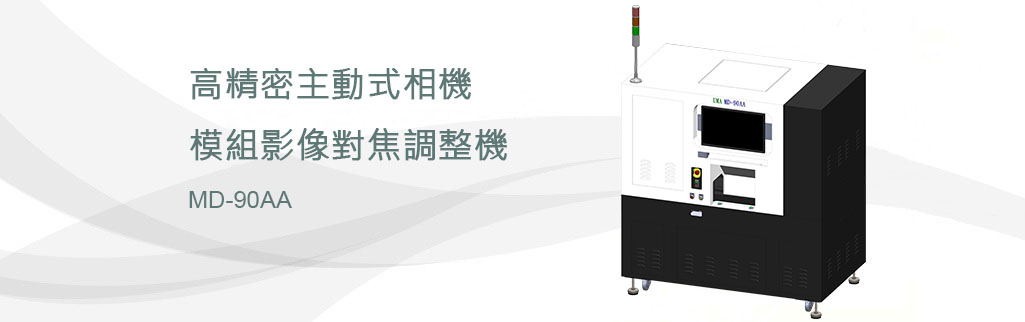

高精密主動式相機模組影像對焦調整機

針對影像模組提供高精密度之全功能鏡頭模組多軸主動式調焦與校正。

根據MTF(Modulation Transfer Function)值的計算結果,透過多軸式的精密調校,可呈現相機模組的最佳影像品質。

搭配迴路軌道式結構,可輕易與自動化生產線整合以提升生產效率。

應用產品

監控、運動相機、與車用相機等影像模組組裝。

特點

✔ 全功能數位化的影像品質調整,透過5或6軸的調校,呈現出鏡頭與影像感測器的最佳搭配效果。

✔ 物距可變系統,程式可控物距切換可滿足不同物距量測的需求。

✔ 高速像平面傾斜及對心調校,進行αβ軸傾斜補正及XY軸對心,快速而確實。

✔ 快速切換治具與料盤設計,可滿足少量多樣需求。

✔ 可配合客戶產線客製規劃。

系列型號

► MD-90AA

► MD-90AA Pro

► MD-90AA CX

2

測試功能

| Sensor Blemish Detect | Check the particles on sensor before AA process |

| Glue width and broken detect | |

| Active Alignment | 6-axis (Sensor) or 5-axis (Lens) active alignment |

| UV Pre Cure | 4 LED heads to proceed UV Pre-cure |

| Through Focus and SFR Curves | Measuring the result before and after Active Alignment |

| MTF and Decenter Test | before and after UV pre-cure |

| Through objective distance scan | Scan MTF variation from 40cm to infinity object distance. |

3

系統規格

| Machine Dimensions | 2036(W)*1130(D)*1800(H) mm |

| Machine Weight | 550KG |

| Power Supply | AC220V/16A |

| Software Operation | Windows 10 64bit |

設備規格

|

Discerption |

Loop-rail conveyer system for automatic in-line production(1) |

| Module Dimensions Limitation | • Lens :~50 mm(W) X 50 mm (L) X 150 mm(H) • PCB Board:~50 mm(W) X 50 mm (L) Note. Lager size parts may need a customized system, which required evaluation by UMA. |

|

(4) |

• Motorized collimators:Objective distance 20cm ~ infinite |

|

(5) |

• X Axis:20mm/0.001mm |

|

(6) |

• X Axis:20mm/0.001mm |

|

(7) |

Wavelength 365nm |

| Cycle Time | ~30 sec/pcs for NF module (UV pre-curing < 10 sec and frame rate>30) |