1

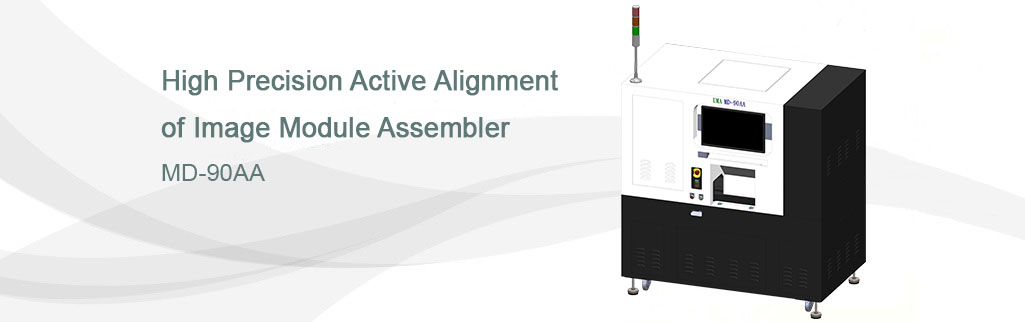

High Precision Camera Module Active Alignment System

MD-90AA Pro Series provides full-function, automatic and high precision active alignment capability for camera module assembly. Whether by applying 6-degree freedom AA on Senor or 5-degree freedom AA on Lens based on MTF calculation, the image quality of camera module is effectively improved. With loop-rail conveyer design, this system can be easily integrated into automatic production line and, therefore, greatly improves production efficiency.

APPLICATION

It can be widely applied to image module assembling of surveillance, cell phone, IP Cam, sports cam, panoramic camera and wide angle lens for cars.

FEATURES

✔ Full-function and digitalized image quality alignment. Optimize image quality by applying 6-degree freedom Sensor AA or 5-degree freedom Lens AA adjustment.

✔ The optical system can be upgrade by program controlled motorized collimator that can meet different objective distances measurement requirements.

✔ High-speed image plane tilt correction and center alignment by conducting αβ axis adjustment and XY axis centering.

✔ The Loop-Rails structure is designed for increasing the manufacturing speed and automatic In-line production.

✔ Thoughtfully designed jig for quickly and easily model switching that can fulfill the demands of variety type but small quantity product; it also can be customized.

✔ The system also can be designed by following client’s requirements of production line.

Series Type

► MD-90AA

► MD-90AA Pro

► MD-90AA CX

2

FUNCTIONS

| Sensor Blemish Detect | Check the particles on sensor before AA process |

| Glue width and broken detect | |

| Active Alignment | 6-axis (Sensor) or 5-axis (Lens) active alignment |

| UV Pre Cure | 4 LED heads to proceed UV Pre-cure |

| Through Focus and SFR Curves | Measuring the result before and after Active Alignment |

| MTF and Decenter Test | before and after UV pre-cure |

| Through objective distance scan | Scan MTF variation from 40cm to infinity object distance. |

3

SPECIFICATIONS

| Machine Dimensions | 2036(W)*1130(D)*1800(H) mm |

| Machine Weight | 550KG |

| Power Supply | AC220V/16A |

| Software Operation | Windows 10 64bit |

|

Discerption |

Loop-rail conveyer system for automatic in-line production(1) |

| Module Dimensions Limitation | • Lens :~50 mm(W) X 50 mm (L) X 150 mm(H) • PCB Board:~50 mm(W) X 50 mm (L) Note. Lager size parts may need a customized system, which required evaluation by UMA. |

|

(4) |

• Motorized collimators:Objective distance 20cm ~ infinite |

|

(5) |

• X Axis:20mm/0.001mm |

|

(6) |

• X Axis:20mm/0.001mm |

|

(7) |

Wavelength 365nm |

| Cycle Time | ~30 sec/pcs for NF module (UV pre-curing < 10 sec and frame rate>30) |